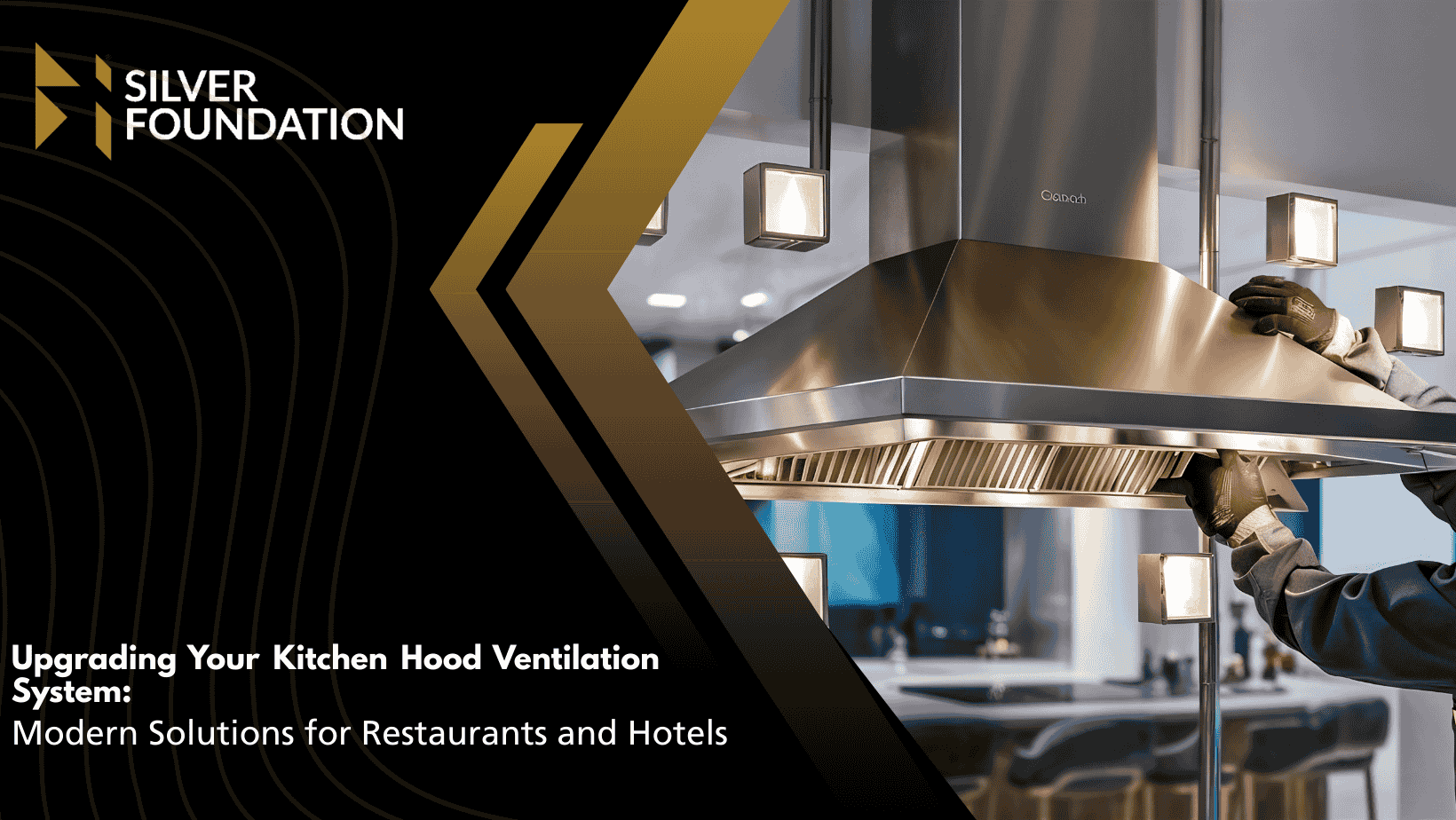

Kitchen hood ventilation is no longer a small detail in commercial kitchens. It plays a key role in keeping air clean, staff safe, and cooking areas comfortable. Today, hotels and restaurants face higher expectations for safety, energy savings, and rule compliance. Old systems often trap smoke, heat, and grease, hurting air quality and team focus. Modern upgrades now bring smarter controls and better airflow. At Silver Foundation, these changes help kitchens work better, and guests feel the difference daily inside.

Busy kitchens have commercial ventilation systems that eliminate smoke, heat, grease, and odours. They help in maintaining the air, staff and food quality. An effective system will suction the polluted air to the food preparation zones and substitute it with fresh air. This balance enables comfortability on long shifts. Adequate ventilation will also help in following proper rules and fire regulations.

If designed properly, hoods help to protect the equipment and reduce the hassle of the cleaning process. They also contribute to the stable cooking performance. A well-functioning hood system is not a choice in the case of restaurants and hotels. It is an integral constituent of day-to-day activities, customer satisfaction and long-term prosperity.

Signs Your Restaurant or Hotel Needs a Ventilation Upgrade

Overheating and Smoking

Overheating and smoke always stay in the kitchen while cooking any dish. But excessive smoke can make the employees uneasy and fatigue. This happens because the air movement around is not sufficient. In case the kitchens remain hot despite the presence of the fans, the hood system is possibly weak. Hence, it requires an upgrade in the near future to carry out daily cooking needs.

Fast Grease Buildup

Walls and ceilings get greasy very quickly. Clogging of filters is very common, which makes cleaning a time-consuming process. Grease buildup is a major warning sign of a poor ventilation system. A modernized system maintains a cleaner and safer kitchen during the busy shifts and busy seasons.

Rising Energy Costs

Energy costs increase without any obvious explanation. Older hood systems are power wasters and draw excessively much air. Motors operate more than necessary. Airflow is better controlled with new designs. With monthly expenses continuing to increase, a ventilation upgrade can reduce the energy consumption and enhance balance and support the daily environment in the kitchen for teams.

Hygiene and Health Hazards

Health inspections are extremely important to measure the quality of the air. A reliable inspection will capture the level of bad grease or smoke. Such problems are likely to result in fines or delays in work. Following safety and code standards balances the airflow and ensures the safety of staff, guests and property owners.

Major Challenges of Traditional Kitchen Hood Systems

Poor Air Balance

Modern hood systems usually transfer out excessive air. This puts strain issues within the building, making doors hard to open. With the last of balance, heating and cooling systems find it hard to work accurately, increasing costs and decreasing the overall efficiency of the kitchen among staff.

Weak Grease Control

Older designs are less effective in grease capture. Once filters get the smoke, it raises the chances of catching fire hazards. With time, ducts also accumulate massive amounts of grease. As a result, it turns into a costly investment in terms of maintenance. Meanwhile, it also brings hurdles into service schedules and puts pressure on kitchen management teams during day-to-day operations.

High Noise Levels

Old hood fans have a higher noise level. There is a constant loud sound which puts pressure on staff. It gets more difficult to communicate during the busy service. This is due to the poor fan design, which leads to vibration. This influences comfort and attention, resulting in errors and slow service in busy kitchens.

Lack of Smart Controls

Outdated systems do not have smart controls. Fans run at full speed all day. This consumes energy and accelerates parts. Hence, as a result, this has led to performance remaining low in both slow and peak seasons. There also comes an inflexibility in kitchens and their inability to run efficiently in the long run.

List of Modern Kitchen Hood Ventilation Solutions

Demand Controlled Ventilation

Demand-controlled ventilation supports adjusting the airflow during the activity of cooking. Measurement of heat and smoke sensors is extremely important. When the demand decreases, the fans slow down their speed. This saves energy and reduces all kinds of noise. It also ensures the constant air balance in the entire duration of servicing. At the end, it increases the comfort of the staff, extends the life cycle of equipment utilized in the kitchen operations daily.

Highly Efficient Grease Filters

Grease filters are highly efficient, meaning they capture maximum smoke and oil. They also help to reduce buildup in ducts. It is easy to clean the filters with proper planning. They also have superior airflow and make hoods work well without incurring extra power usage. Thus, filters have a long service life in high-traffic commercial kitchens that have consistent service performance.

Low Profile Hood Designs

The source capture is boosted by the low-profile hood designs. They are located close to the cooking equipment to limit the smoke. These designs work well in open kitchens of hotels and restaurants where the looks, comfort, and performance must work together every day with the guests and employees.

Combination Makeup Air Systems

The replacement of the exhausted air is done softly through integrated makeup air systems. They keep pressure balanced, ensuring an improved heating and cooling. It also offers a stable condition that facilitates good cooking, comfort and regular use of energy without stressing building systems when using long hours in a busy commercial kitchen in day-to-day life.

Smart Control Panels

Smart control panels also have clear system feedback. Operators can get fan status and alerts. It also makes the adjustments simple, along with accurate data to plan proper maintenance. Such facilities help the managers to make effective decisions concerning the performance of kitchen ventilation. It also reduces downtime, error and stress in the daily running of the restaurant by the teams and service leaders.

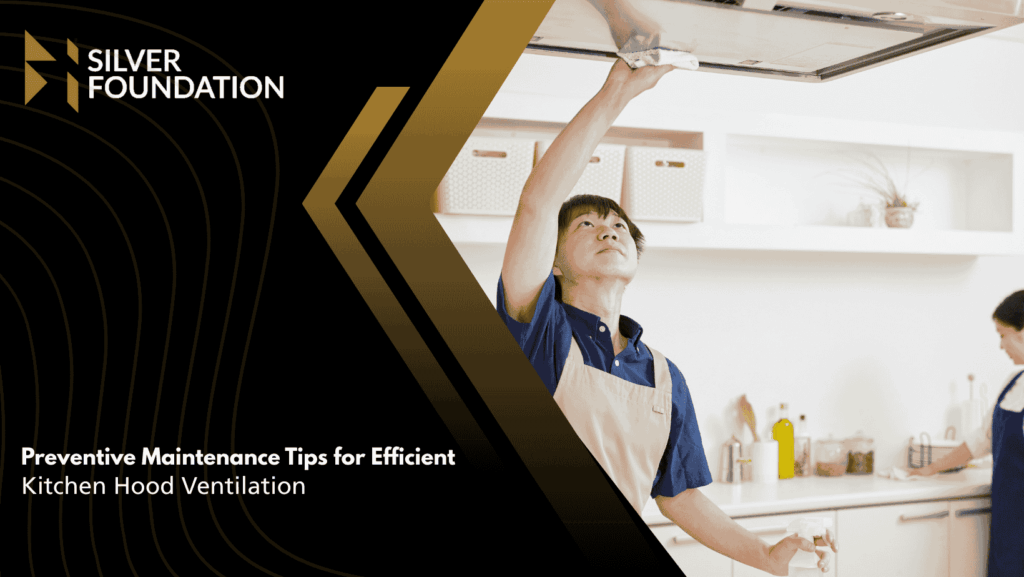

Quick Maintenance and Best Practices for Modern Systems

The modern kitchen hood systems should be serviced on a regular basis to ensure their functionality. Plan a schedule to wash the filters to make sure that there is complete protection of airflow. Also, inspect the fans, wearable sensors, and belts. Wipe the control panels with great attention. Check the hidden ducts to stop accumulations. Meanwhile, workers should be trained to report at an early stage in case of any noise or bad smell.

Regular maintenance will improve the lifespan of equipment and help to save maximum energy. It also brings maximum safety and stability in overall hood performance. Through the simple routine checks, kitchens are kept in a comfortable, serviceable state to meet the daily service needs. This will reduce downtime, protect the health of the staff, and ensure operations will be performed well even during peak seasons of the service.

Conclusion

Upgrading kitchen hood ventilation is essential for safe, clean, and smooth operations. Modern systems improve fire safety, air quality, energy use, and legal compliance while keeping staff comfortable. For restaurant and hotel operators, this upgrade supports daily performance and brand trust. With solutions from Silver Foundation, ventilation becomes a smart long-term investment, not just a basic requirement for future growth.

Frequently Asked Questions

How often should a commercial kitchen hood system be upgraded?

Most systems benefit from evaluation every 10–15 years, or sooner if energy costs, compliance issues, or kitchen performance decline.

What is demand control kitchen ventilation?

DCKV adjusts exhaust fan speed automatically based on cooking activity, reducing energy use while maintaining proper smoke and heat removal.

Are modern kitchen hood systems quieter?

Yes, variable-speed fans and improved hood designs significantly reduce noise compared to traditional constant-speed ventilation systems.

Do ventilation upgrades help with fire safety?

Modern systems improve grease capture and airflow control, reducing fire risk and helping kitchens meet NFPA and local fire safety codes.